Christmas Throwback: Space shuttle orbiter road test, 1984

Back in 1984, we conducted our famous Christmas 'road' test on one of NASA's space shuttle orbiters, here reproduced in full

Back in 1984, we conducted our famous Christmas 'road' test on one of NASA's space shuttle orbiters, here reproduced in full

Autocar does not normally test heavy commercial vehicles, but we have decided to make an exception, such are the important technological implications of a recent American development in transportation.

Initial engineering, design and cost studies for a reusable shuttle first began in early 1970, with a decision on the final configuration — two solid propellant booster units augmenting three liquid-powered engines of the main orbiter plus a large external fuel tank — taken in 1972.

It is perhaps some measure of the work which had to be done and the problems which had to be overcome that it took nine years before a working vehicle made its first trip. Since that time, there have been 11 successful outings, justifying the immense government expenditure on the project. The space shuttle is perhaps best described as an aerospace vehicle which takes off like a rocket, can manoeuvre in orbit after carrying a payload of up to 65,000lb and then return to land on a normal concrete runway.

Its versatility and quick turnaround time means it provides, for the first time, a viable way of carrying out a number of tasks which were previously considered impossible. These include the maintenance and repair of unmanned satellites, or their 'collection' for repairs, the placing in orbit of interplanetary vehicles, the provision of a platform for scientific experiments and the carrying of components for larger projects. The space shuttle has three main units: the orbiter, the external fuel tank and two solid rocket boosters, each with a thrust of 2.6 million pounds.

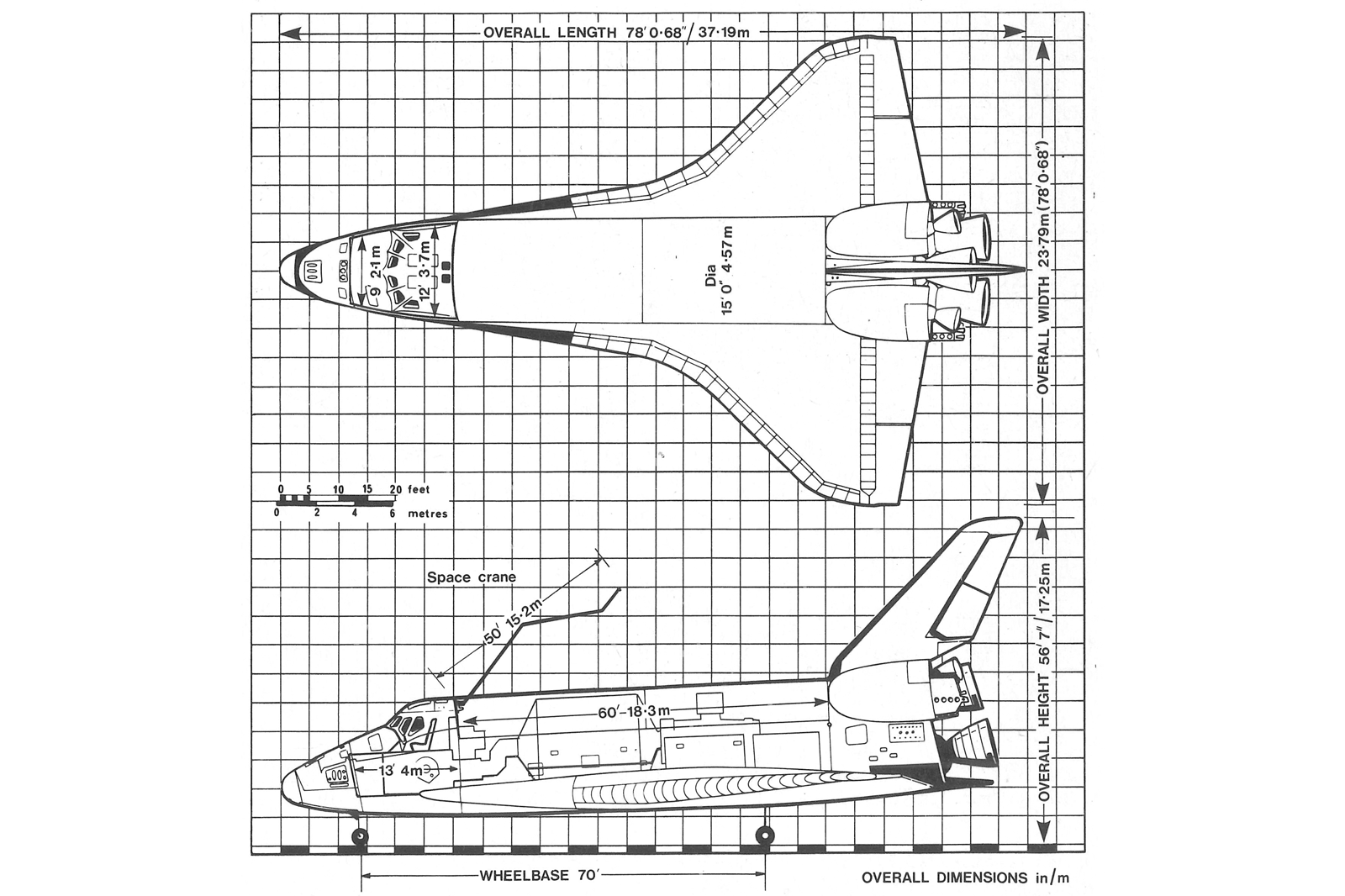

The orbiter, which is the passenger and payload carrying part of the system, is somewhat larger than many more conventional commercial vehicles. With a length of 121ft, a width of 79ft and a dry weight of 150,000lb, it approximates the dimensions of a DC9 jet airliner. Access to the orbiter is a bit unorthodox; having made your way up the gantry at NASA's John F Kennedy Space Centre in Florida, you clamber in through a circular hatchway in the nearside front of the vehicle and then up a narrow stairway to the cockpit. Since the shuttle is standing vertically at this point, it is necessary to lie on one of the Nomex-covered seats, held in place by a four-point harness.

The orbiter, which is the passenger and payload carrying part of the system, is somewhat larger than many more conventional commercial vehicles. With a length of 121ft, a width of 79ft and a dry weight of 150,000lb, it approximates the dimensions of a DC9 jet airliner. Access to the orbiter is a bit unorthodox; having made your way up the gantry at NASA's John F Kennedy Space Centre in Florida, you clamber in through a circular hatchway in the nearside front of the vehicle and then up a narrow stairway to the cockpit. Since the shuttle is standing vertically at this point, it is necessary to lie on one of the Nomex-covered seats, held in place by a four-point harness.

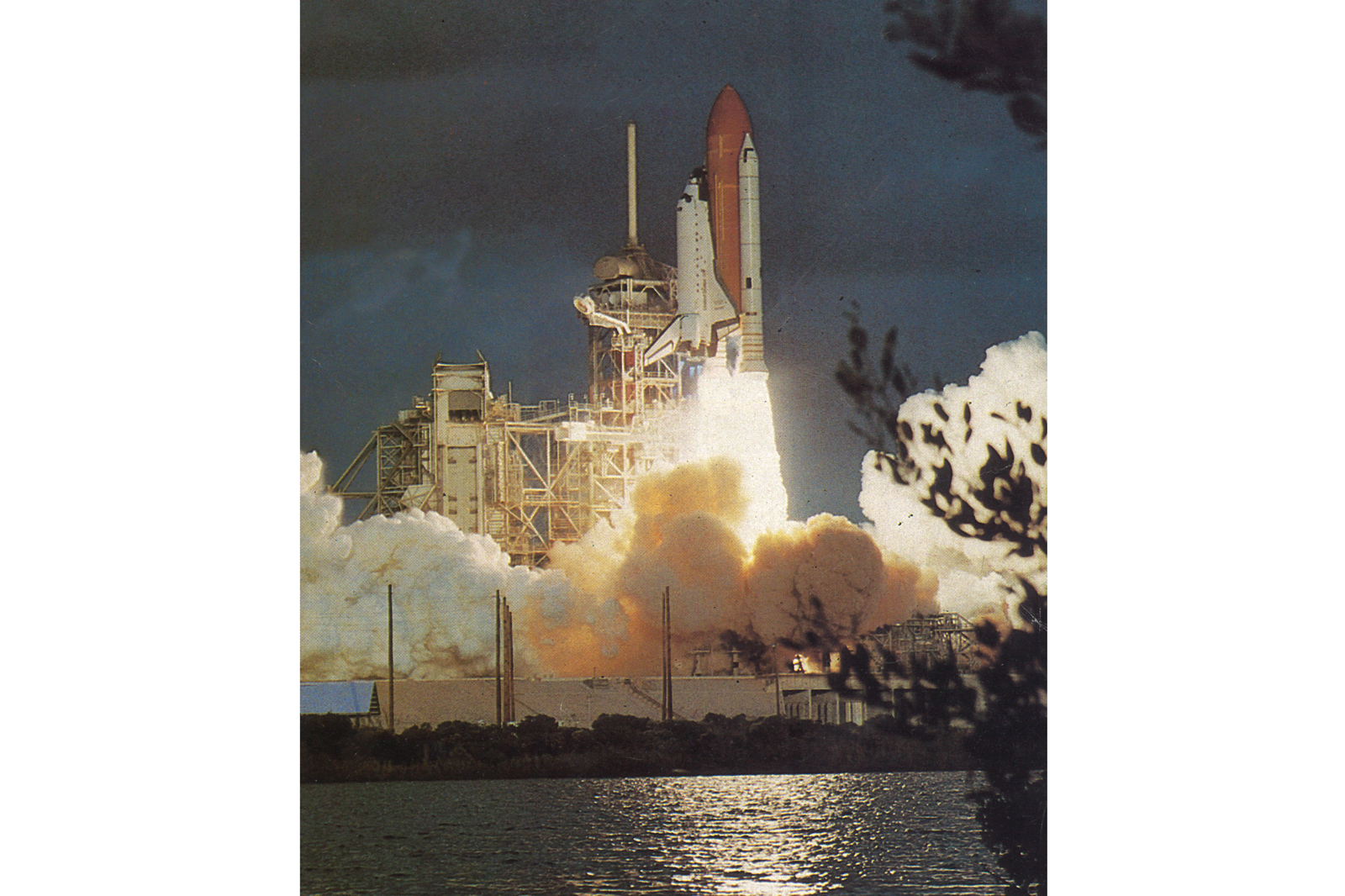

The occupants remain in this position, carrying out checks on the various systems, and there is no real sign of mechanical activity until approximately six seconds before the engines start. At this point, there is what might best be described as a moan from the back of the shuttle, which builds in intensity along with a distant vibration as the two, huge solid propellant engines on either side of the vehicle fire up. The orbiter goes through an oscillation, dubbed the 'twang' factor, just before the explosive pyrotechnics are fired to release the hold-downs which restrain the shuttle.

At this point, there is almost the feeling of a 'kick in the tail' as the tower, which had been helping to support the vehicle, can be seen disappearing. With a total of five engines on full song, power delivery has to be classed as mightily impressive, albeit mightily unrefined. The noise and vibration are such that it is necessary to shout over your helmet intercom to be heard by your fellow passengers. To add to all this activity, after about 10 seconds, the vehicle goes into a roll and a glance out of the windows reveals swampland below and a blue sky ahead.

After what seems like quite a lengthy period, but is really only about two minutes, the solid propellant engines detach themselves and fall away towards Earth, 27-and-a-half miles distant. The previous levels of noise, vibration and harshness, diminish drastically now, not just because the rough-burning power units have been jettisoned, but because the thick air of the lower atmosphere and the sound barrier — both vibration-inducing — have long been left behind.

After what seems like quite a lengthy period, but is really only about two minutes, the solid propellant engines detach themselves and fall away towards Earth, 27-and-a-half miles distant. The previous levels of noise, vibration and harshness, diminish drastically now, not just because the rough-burning power units have been jettisoned, but because the thick air of the lower atmosphere and the sound barrier — both vibration-inducing — have long been left behind.

The ride for about the next six minutes is as impressively smooth as the first two were dramatically rough. The speed of the shuttle continues to increase as it gets lighter and the main engines throttle back so the vehicle doesn't exceed its 3g (plus margin) operating limit. The occupants of the orbiter are being pushed back into their seats with their bodies weighing three times what they normally would. At about the eight-and-a-half-minute mark, and with Earth 68 miles away, the main fuel tank is released, the engines cut abruptly and you are suddenly just floating in the straps of your seat harness, as are all of the other tethered objects around you — orbit has been successfully achieved. The speed of the shuttle is now 17,741mph.

Economy

Unfortunately, this is not a particularly strong point of the vehicle, but then one must bear in mind the power being produced and the performance which is on tap. The worst period for fuel consumption is at liftoff, when the liquid hydrogen and oxygen are being used at the rate of 1 gallon per 5ft. This, of course, continues for the first eight powered minutes of the journey, which is why such a large external fuel tank is required. Fuel can be supplied to the engines at the rate of about 37,736 gallons per minute of hydrogen and about 14,000 gallons per minute of oxygen. Interestingly, the combination of a staged combustion cycle coupled with high combustion chamber pressures and rapid mixing of the propellants leads to a combustion efficiency of 99%.

Safety

Safety

One of the great operational fears is an onboard fire and, to that end, the builders, Rockwell International, have plumbed in extensive extinguisher systems as well as located hand-held extinguishers at points where there is even the remotest fire risk. In addition, all materials onboard are fire-resistant and tested for outgassing and flammability. Something which could also be considered under safety are the hundreds of thousands of heat-resistant tiles which cover the outer surface of the orbiter. Initially, there was much concern in the media over the fact that they had a tendency to loosen and drop off and, even now, the heat and vibration usually causes a number of tiles to be left behind on the launch pad. NASA officials, however, stress that at no time have tiles ever been lost from critical areas of the Orbiter.

Technical focus

Without a doubt, the most interesting element of the shuttle system must be the power source. In view of the massive payloads which can be carried (up to 65,000lb) and the speeds required for successful operation (nearly 18,000mph), Rockwell International engineers decided on a three-engine configuration. Instead of going for petrol-powered piston engines, however, they chose high-performance liquid hydrogen-liquid oxygen units capable of generating various levels of thrust (they prefer to talk of power in terms of pounds of thrust rather than more conventional horsepower). The power is developed by employing these high-energy propellants in a staged combustion cycle.

They are partially combusted in dual preburners to produce high-pressure hot gas which drives turbo pumps, with the process being completed in the main combustion chamber. Each of the shuttle's main engines operates at a liquid oxygen-liquid hydrogen mixture ratio of 6 to 1 to produce a thrust at sea level of 375,000lb (1,668 kilonewtons). The engines can be controlled over a thrust range of 65-109% of the rated power band to provide the impetus necessary for liftoff and the initial ascent phase, and then throttled back to limit acceleration to 3g during the final ascent phase.

They are partially combusted in dual preburners to produce high-pressure hot gas which drives turbo pumps, with the process being completed in the main combustion chamber. Each of the shuttle's main engines operates at a liquid oxygen-liquid hydrogen mixture ratio of 6 to 1 to produce a thrust at sea level of 375,000lb (1,668 kilonewtons). The engines can be controlled over a thrust range of 65-109% of the rated power band to provide the impetus necessary for liftoff and the initial ascent phase, and then throttled back to limit acceleration to 3g during the final ascent phase.

The engines are gimbaled, or pointed directionally to provide control of pitch, yaw and roll during the orbiter boost phase. The three engines are linked by the new familiar electronic management system. This black box includes a computer which integrates commands from the orbiter with data from the engines.

Behind the wheel

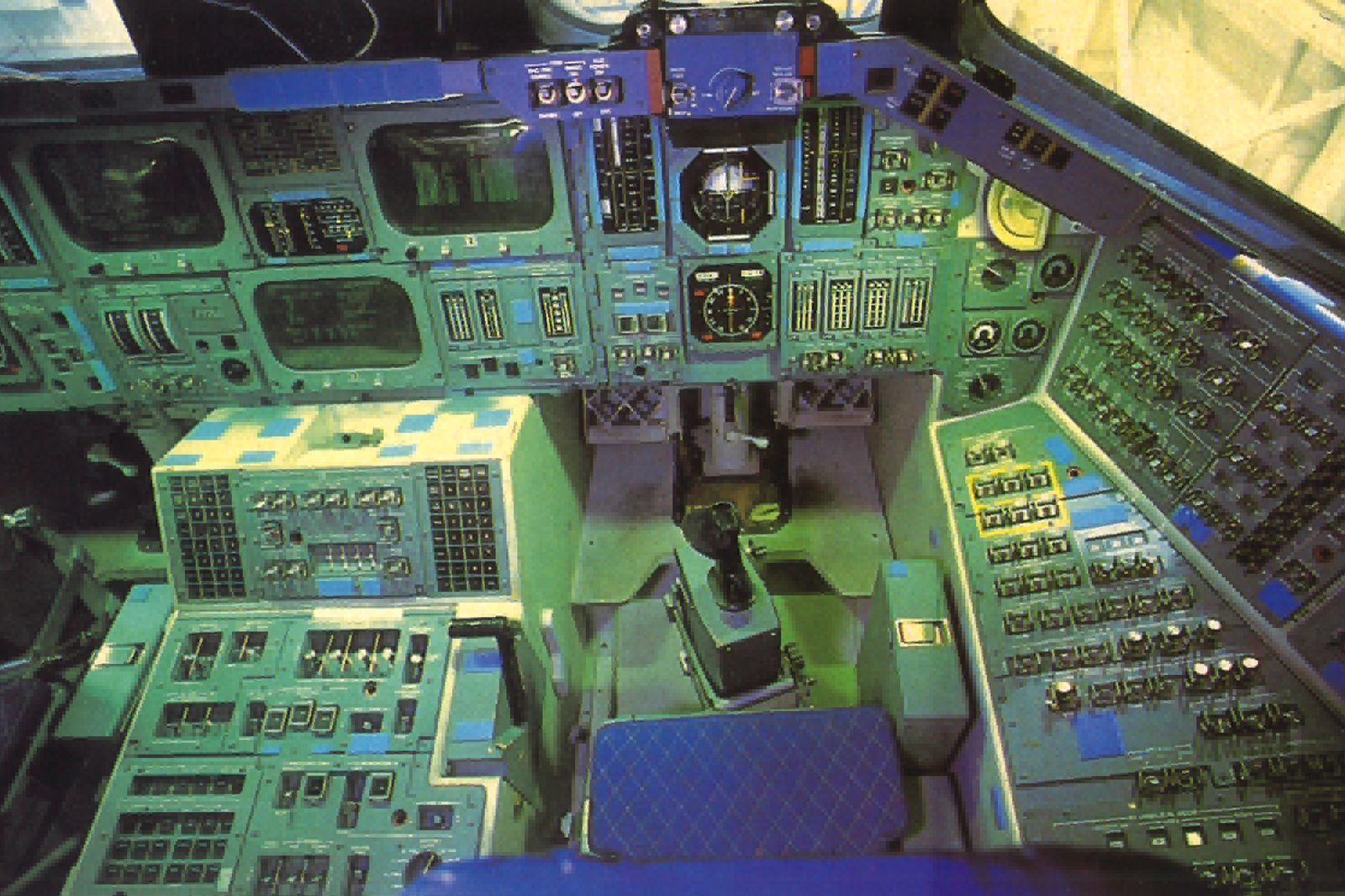

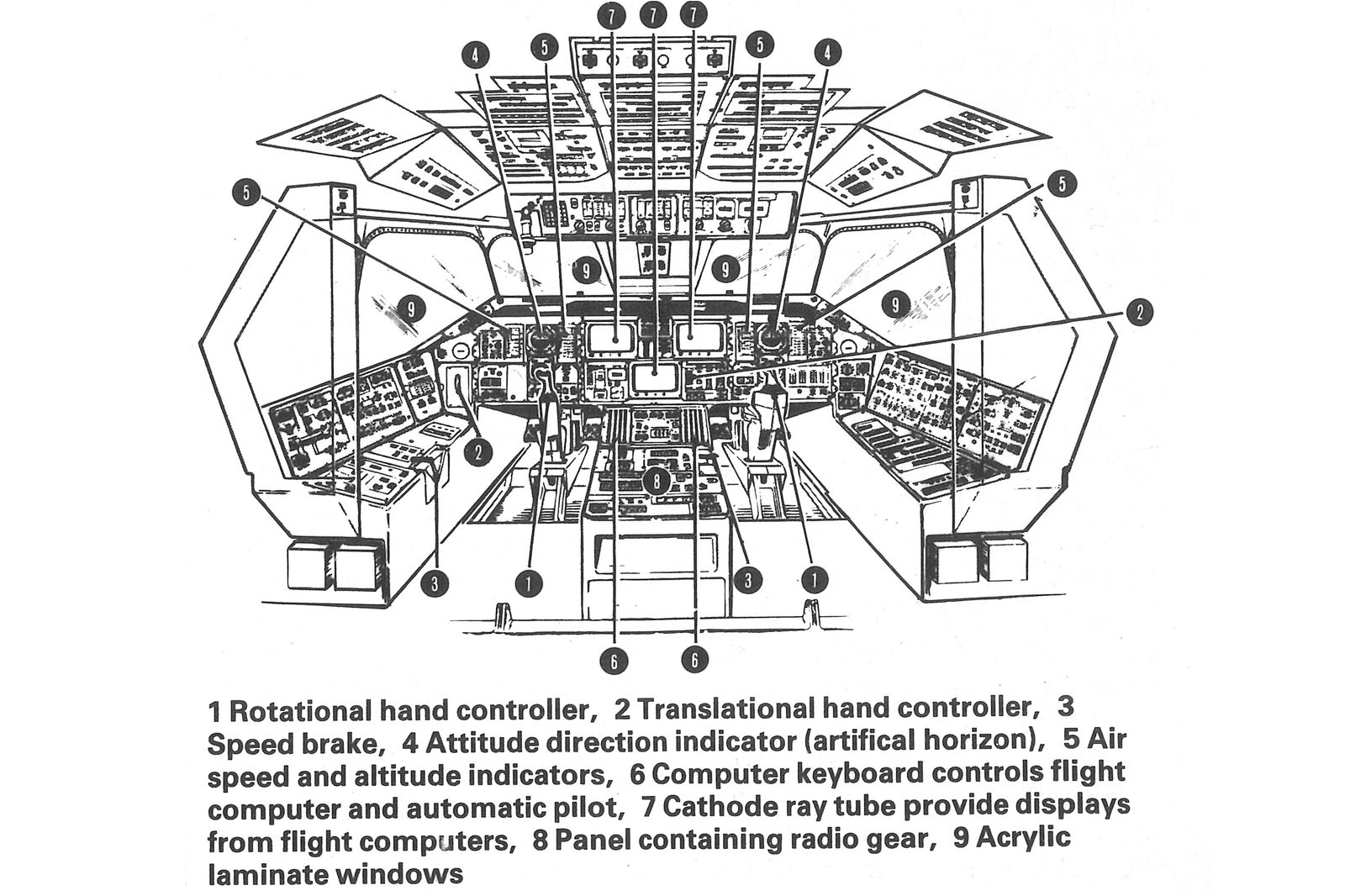

It is probably safe to say that the complexity of the shuttle's instruments would not be acceptable to the average car driver. Having clambered over the large centre console and into the seat the driver is confronted by a zigzag array of switches and circuit breakers, four television-type screens, three computer keyboards, a gyroscopic horizon indicator and, immediately ahead, a hand controller. Some of these items are used only when going into orbit, some only while in orbit and others only for the return journey. It was originally intended that the instruments and controls should be as simple and straightforward as possible but, as with many complicated undertakings, things tend to grow like topsy. It must also be said that everything in the cockpit is deemed essential to the smooth and safe operation of the orbiter.

The driver of a conventional car might also be somewhat nonplussed to discover that there is no steering wheel in the shuttle. Instead, there is a hand controller which moves in three axes — pitch, roll and yaw — and allows the vehicle to be controlled precisely with no more than gentle movements of the wrist. Despite its bulk, the orbiter does not respond well to a harsh touch on the controls — it will, however, reward smoothness and precision on the part of the user. Such is the complication of the shuttle's cockpit that it seems to bear more relation to that of a commercial airliner than anything else.

Living with the shuttle

Living with the shuttle

The majority of the orbiter's length is given over to the carriage of cargo rather than people. The working crew can include up to seven people and accommodation, it must be said, is limited but then the purpose for which the shuttle was intended must be borne in mind. Its cargo bay, protected by hinged payload bay doors, is a cavernous 60 x 15ft and is altered in detail after every trip to suit the requirements of the next mission. Just like a freighter, there is also a manipulator arm which permits the retrieval or deployment of various objects during orbit.

The heating and ventilation system is housed beneath the lower deck and is responsible not just for temperature control but also for atmospheric pressure, humidity and carbon dioxide levels. Electrical power for the space shuttle and payloads is generated by three fuel cells which use cryogenically stored hydrogen and oxygen to produce 1530kWh of energy. Engine compartment accessibility is apparently not a problem despite there being three engines to deal with rather than one.

Previously, on vehicles of this type, there was no question of servicing or maintenance since engines and other components were used only once and were deemed expendable. The main power units of the orbiter can be serviced without the need to be removed from the vehicle and most components can be reasonably easily replaced in the field without the need for extensive engine recalibration or test firing. This is a distinct advantage since there are few places where rocket engines can be fired up without upsetting neighbours.

Road behaviour

During the orbital stage of the journey, the shuttle moves precisely, effortlessly and quietly and is frequently on the automatic mode as the occupants go about their duties. The orbiter can be easily manoeuvred, the large reaction control engines permitting it to be moved about its axes and thereby aimed at the sky, Earth or any other points of interest. It is on re-entry, though — normally from 45,000ft downwards — where automatic control ends and human control takes over.

The handling characteristics of the orbiter are precise enough, although the control system could be likened to the Bosch ABS and recently introduced ASR systems. That is, there is an electronic 'black box' between the human input and the control surfaces, rather than any sort of direct cable link. This electronic intercession does give the controls a slightly artificial feel but, having said that, their relative crispness of response is quite acceptable, especially bearing in mind the considerable size of orbiter. One characteristic which has become apparent is that, on the final descent to the runway, with the vehicle at about 2,000ft and the descent angle altered from a steep 19deg to about 11/2deg, it is particularly insensitive to changes in pitch.

It is, therefore, best to get the alignment set while several hundred yards out and then restrict any course corrections to very small ones. The orbiter normally touches down at about 225mph with a descent rate of 2-3fps. Taking the load at this point is the triangle configuration landing gear, with a pair of wheels on each corner. All three units are hydraulically controlled and will reach the fully extended position within a maximum of 10 seconds, particularly important since the deployment of the undercarriage is left to the very last instant before touchdown.

Conventional gas/hydraulic shock absorbers help absorb the impact of landing, while steering control, on touchdown, is by the nose wheel and rudder. Similarly, braking is a two-pronged affair with the split vertical stabiliser in the rudder, which opens out to create a speed brake, augmented by carbon-lined beryllium brakes on each of the four main wheels with one anti-skid system. Perhaps the most reassuring element when it comes to stopping the orbiter on its return is the fact that it has a three-mile runway in which to slow down — theoretically adequate for it to stop without braking.

REFINEMENT

The shuttle exhibits great contrasts in this department. All normally accepted levels of noise, vibration and harshness are exceeded in the first two minutes of the journey, after which time there is such a marked improvement that it is almost impossible to believe that it is the same vehicle. Once in orbit, the main noise sources are the large reaction control engines which are used for manoeuvring. There are more than 30 of these, each with about 800lb of thrust on tap and, despite the absence of any sound-transmitting air outside, the front engines make a noise like distant artillery, the structure of the orbiter itself acting as a sort of sounding board.

Most of the time, these engines, plus six, smaller 25lb thrust units, are on automatic mode, simply firing on the commands of the onboard computers in order to maintain position. There are also two 6,000lb thrust manoeuvring engines which are used to alter the shuttle's orbit as well as slow it down to bring it out of orbit. By comparison with the launch, re-entry is a much tamer affair, partly because there is engine noise and partly because the orbiter seldom achieves more than 1.5-1.6g.

The two main occurrences from a refinement point of view become evident as the shuttle slows down to around the 2500-2800mph mark — there is a marked rumble as it hits the thicker air of the atmosphere and passengers are pulled forward into their harness straps by the deceleration — and at 40,000-50,000ft, when a shudder goes through the orbiter as it slows below the speed of sound. Neither of these are near the severity of the noise and vibration of the launch period.

The two main occurrences from a refinement point of view become evident as the shuttle slows down to around the 2500-2800mph mark — there is a marked rumble as it hits the thicker air of the atmosphere and passengers are pulled forward into their harness straps by the deceleration — and at 40,000-50,000ft, when a shudder goes through the orbiter as it slows below the speed of sound. Neither of these are near the severity of the noise and vibration of the launch period.

VERDICT

With a price tag of $1.2 billion, the orbiter cannot be considered an inexpensive vehicle by any stretch of the imagination. Even so, there are at present three in existence — all in the US — with a fourth to be delivered in the spring of 1985. Nor is the recommended retail price the end of the expenditure for the potential owner since a complete launch package, which includes training, preparation of the vehicle, launch, orbital operations, landing and transporting it back to the launch pad so that the process can start all over again, costs $200 million.

Fuel costs cannot be overlooked either. One trip consumes $385,000 of liquid hydrogen and oxygen and $13 million of solid propellant. Having said that, one must also take into account the demands being made of the orbiter and the distances being covered. For instance, although the vehicle is scheduled to return to the manufacturer after every 20 journeys for "modest refurbishment", it must be so borne in mind that one Earth orbit is approximately 29,900 miles and the minimum journey length to date was 36 orbits or 1,076,400 miles.

In addition, it is expected to withstand a maximum speed of 17,500mph, a maximum temperature on re-entry of 1260deg C (2300deg F) and carry up to 65,000lb of valuable cargo. The space shuttle may be one of the rarest and most expensive of modern vehicles but, without a doubt, the possibilities which it opens up for mankind also make it easily the most exciting. As Commander John Young said of the shuttle at the end of its first complete journey, it’s "a fantastic flying machine". Few would be tempted to contradict him.

Comments

Post a Comment